|

1. Origin of ZDHC

Since 2013, under the impetus of Greenpeace, some internationally renowned textile and apparel brands or retailers have begun to further strengthen the environmental management of their supply chains. One of the important contents is to ban or limit the use of some chemicals that are dangerous to the environment, organisms and humans in the production process, and achieve the goal of zero emission of 11 types of toxic and harmful substances by 2020. This is where the ZDHC program for the textile industry comes in.

The ZDHC program now consists of 23 signatory brands, 27 value chain associations, and 13 associations that form environmental control agreements. Among them, the signed brands include ADIDAS, BURBERRY, GAP, Li Ning LEVI STARAUSS&CO, HM, INDITEX, M&S, NIKE, ESPRIT and other 23 well-known brands from the global textile industry.

In 2015, ZDHC published the List of Restricted Substances for Production (MRSL) ZDHC MRSL V1.1, which restricts the intentional use of chemical substances in the manufacturing process of textile, clothing and footwear components manufacturing plants. The limits of acceptable concentrations of these chemicals in chemical formulations are specified during production. The aim is to manage the use of these chemicals by suppliers and to phase out these hazardous substances in the production process.

In 2016, the ZDHC Wastewater Testing Guidelines were published, which set out sampling and testing methods for wastewater testing to verify whether the production restricted substances list is being implemented in the production process.

Due to the long and difficult list of chemical restricted substances, the environmental quality of the product is closely related to the dyes, auxiliaries, formulations and production processes used in the factory, and will also have an impact on the generated sewage and residues in the sewage, so systematic management is required, but also the corresponding professional knowledge is needed.

2. Preparation for ZDHC certification of our products

From the very beginning, the company has closely followed the development of ZDHC. In 2019, the company actively contacted and conducted ZDHC compliance inspection and certification of the company's microbial control series products - antibacterial finishing agent, antibacterial and mildew resistant finishing agent, etc. In 2022, the antibacterial finishing agent JYK ABDO-120 and antibacterial and mildew resistant finishing agent JYK ABF-248 were reviewed.

In order to conduct the certification, the company sorted out the quality management system of the company according to the provisions of ZDHC, established the quality manual and procedure documents, and established the relevant production quality manual, laying the foundation for ZDHC certification.

3. ZDHC testing and certification

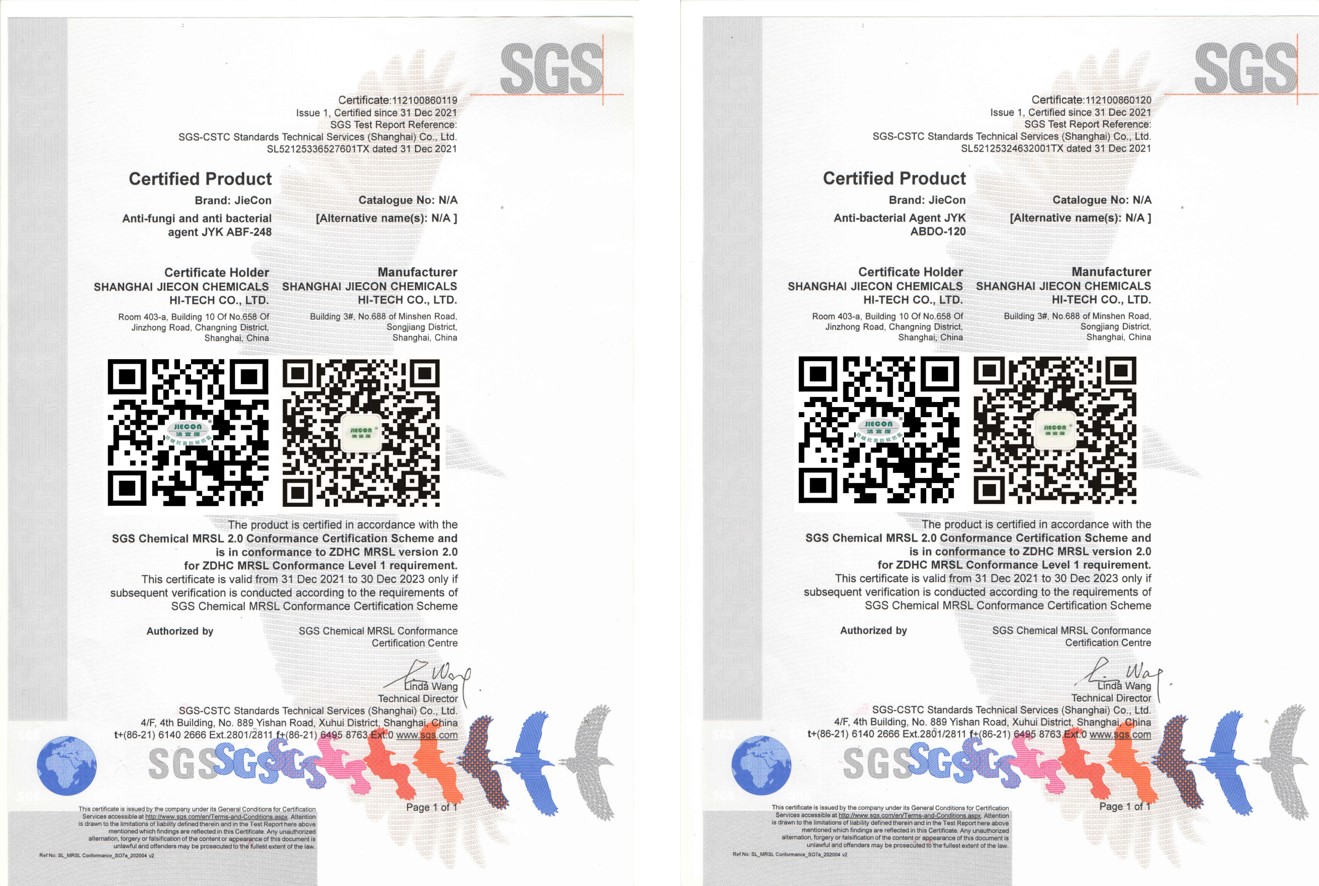

After careful preparation in the early stage, SGS sent staff to the production site of our factory for sampling analysis and testing, and finally issued ZDHC certificates according to the relevant product documents submitted by our company, after synthesis, respectively as follows:

Warmly welcome relevant units and brands, and actively negotiate with our company to seek common development.

We will continue to pay attention to the latest international compliance regulations, and actively participate in them, integrate into them, and keep up with the development pulse of the times.

|